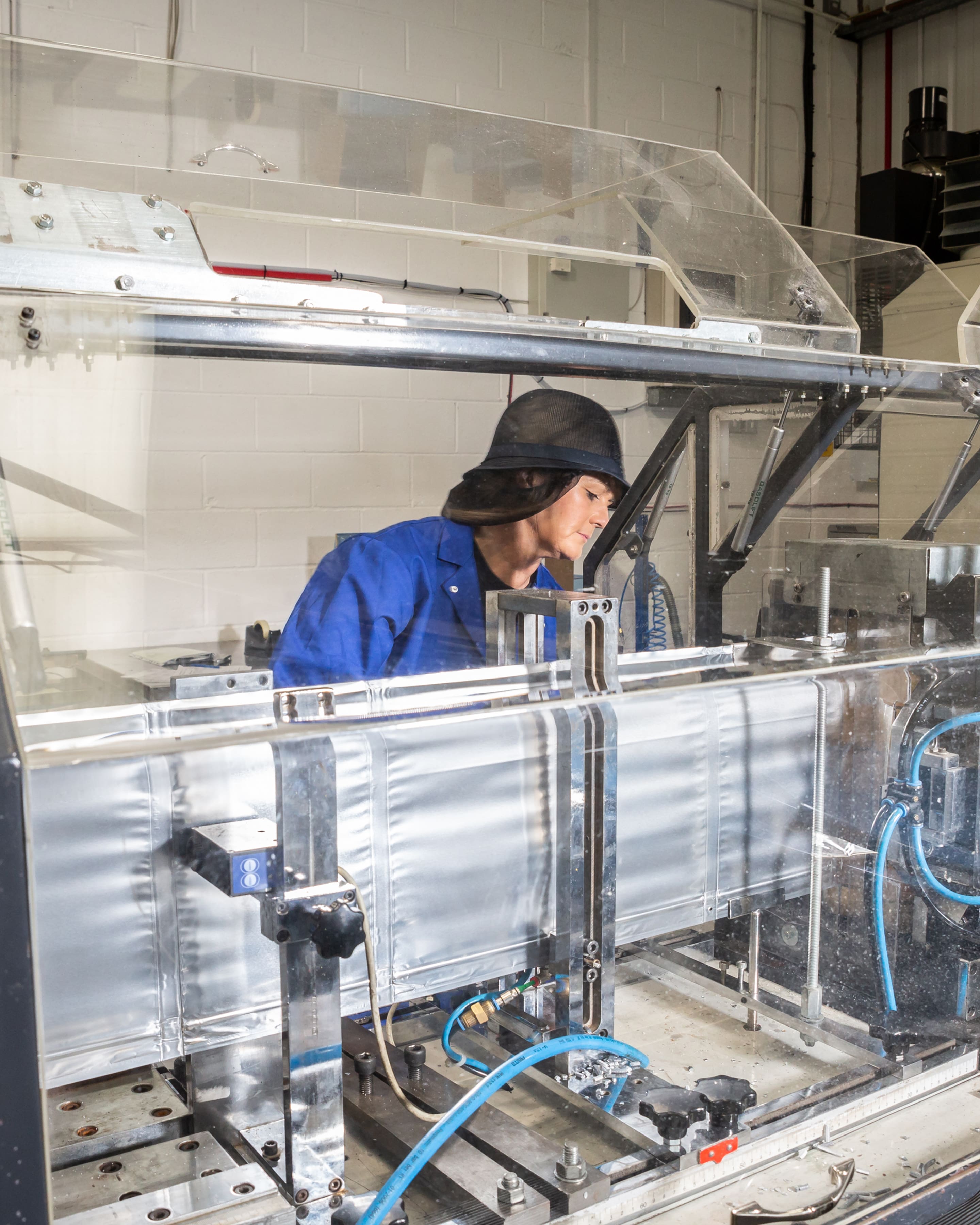

Pouch Conversion

Question: when is a laminate not just a laminate? Answer: when it has been converted into a pouch.

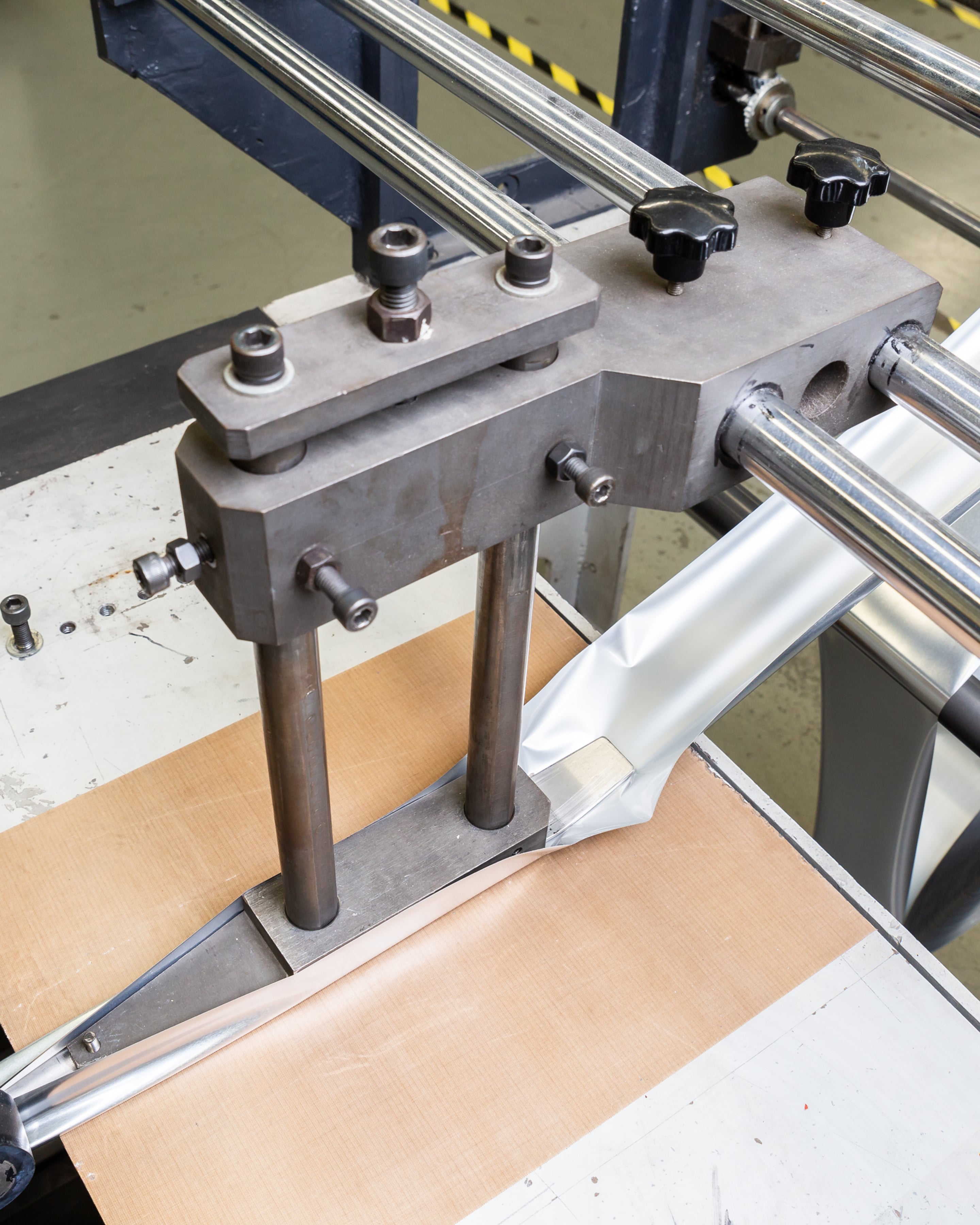

Moore and Buckle makes pouches for food and beverage, aerospace, agriculture, cosmetic and pharmaceutical industries. They come in many shapes and sizes but the principle behind each is the same. Laminate is folded and heat applied to form the seals that make the pouch.

We have six pouching machines on-site giving us complete flexibility on the type and size of pouch made and laminate used. As long as it has a recognised sealing layer, we can use your laminate or create our own to convert into bags, which can be plain or given a high quality printed finish.

We make all types of packaging bags including:

• Doy Packs (stand up pouches)

• Back Seam Bags

• Back Seam Side Gusset Bags

• Quad Seal Back Seam Side Gusset Bags

• Three-side Seal Bags

• Lap Seal Bags

• “L” seal Bags

• Finger lift taped bag options

• Tamper proof bags

• Necked pouches

• Compartmental pouches

Additional features that can be added to your specification:

• Re-Sealable Grippers

• “V” Tear notches and Nicks

• Euro-slots

• Hanging holes

• Spouts

• Nozzles

• K Seals

• Necked seals

Moore and Buckle specialises in pouch conversion that is technically demanding and our team of experts is always happy to answer your questions and give advice. We are just as happy quoting for large, medium or small production runs.

Need a quick answer? Contact us on the form below or call 01744 733066

Need a quick answer? Contact us on the form below or call 01744 733066