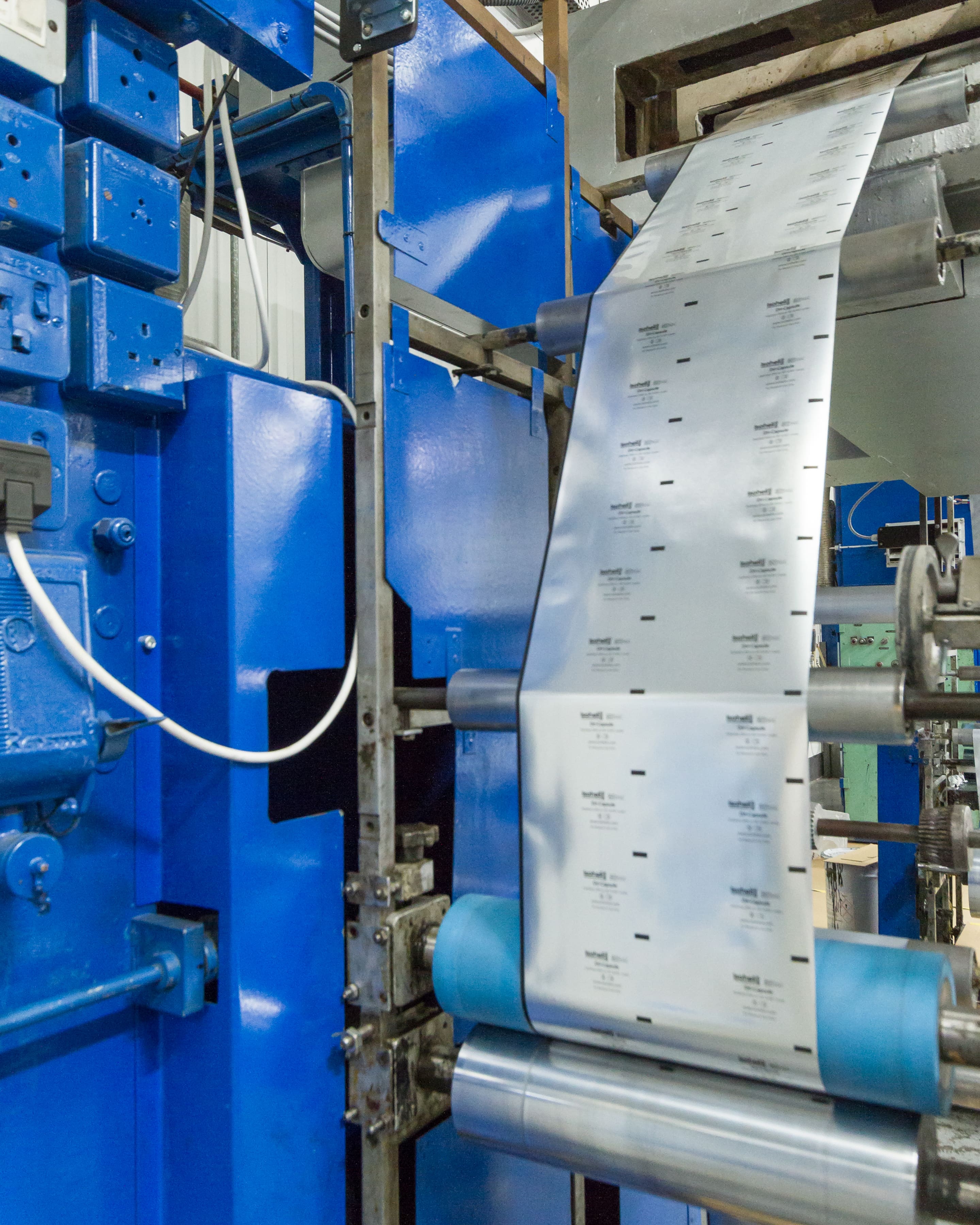

Laminating and Material Supply for Packaging

One of the secrets of great flexible packaging is using exactly the right laminate to make your bags or pouches.

And, at Moore and Buckle, we know there is absolutely no substitute for experience and finely honed skills when creating laminates.

Sticking different types of film together to make a laminate is difficult enough. But knowing which combinations of film will provide exactly the right properties for a customer’s packaging is something else.

It took us months of trials to create the pouches that now keep seeds viable for at least 25 years at the Global Seed Bank in the Arctic Circle, stored at a constant temperature of -18ºC. But we did it, thanks to our team’s skills and our narrow width (330mm. max) laminating and coating machine, which is ideal for short run or development work. This can either be for our customer’s laminates, our own materials or a combination of the two.

In addition, we hold upto 80 different finished laminates on site, available in various widths up to 1650mm. We can supply any of our materials to a required width and reel length with no minimum order quantities. We work with water based and some solvent based adhesives and are happy to collaborate with customers and their staff on solving technical issues such as improving slip and oxy-drying.

We have also been involved in a number of our customers’ own projects where new product developments have been explored and resolved. This can happen by simply providing an experienced machine operator supported by our own technical team.

Call our sales team for a quote today. If you prefer, drop us a quick email and we’ll get straight back to you. And remember, we never require a minimum quantity order.

Need a quick answer? Contact us on the form below or call 01744 733066

Need a quick answer? Contact us on the form below or call 01744 733066